Quality and Service

Quality Control & Traceability

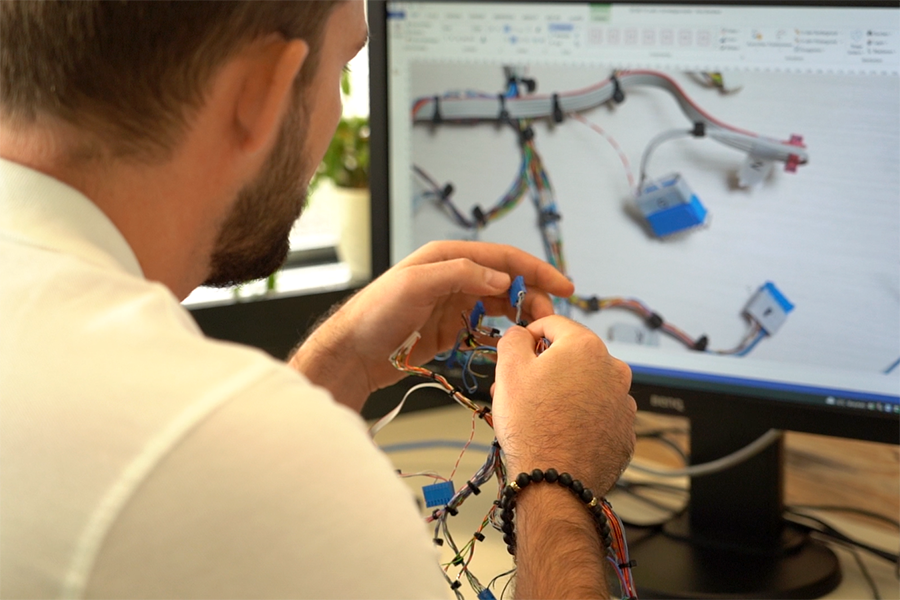

At H&S Kabeltechnik, we place great importance on quality – from production to delivery. Our internal quality assurance ensures that every cable assembly meets our high standards and that our customers receive only flawless products.

Electrical testing and final inspection

Each product undergoes electrical testing before dispatch to rule out faults such as polarity reversal, cable breaks or short circuits. We monitor every step of the manufacturing process to guarantee the highest quality. Samples and detailed documentation ensure that problems are identified at an early stage.

Only through this careful testing can we ensure that our customers receive 100% tested cable assemblies – a quality we are particularly proud of.

Full traceability

Since 2017, we have been able to guarantee 100% traceability for every manufactured product. This means that all production steps are electronically recorded and documented in a traceable manner – from cutting and crimping to assembly and final testing. In this way, we guarantee maximum transparency, quality assurance and traceability for our customers.

Certifications

Our processes are certified according to ISO 9001:2015, and we meet the strict requirements of UL certification. This underlines our commitment to quality and safety in cable assembly. You can also find our certificates in the download area.