Production

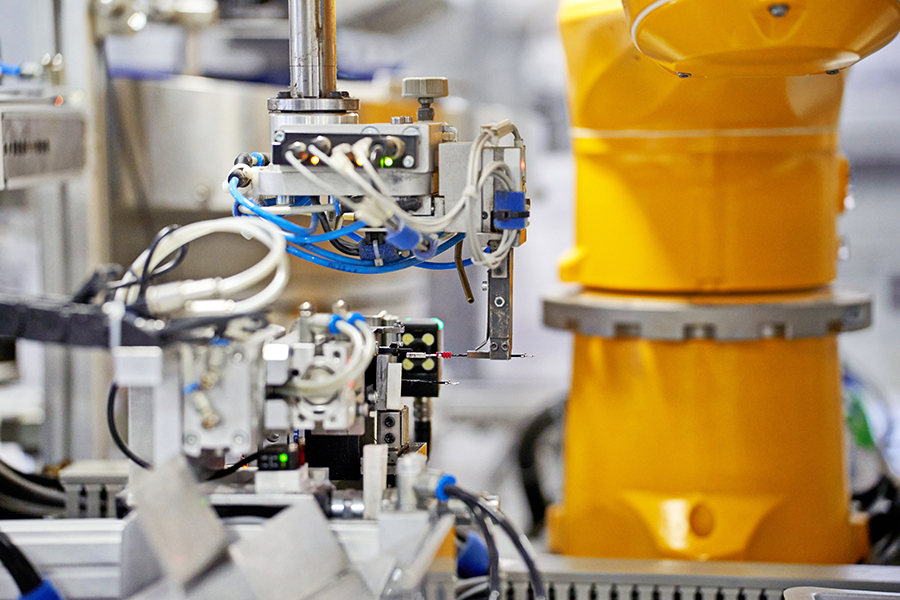

Cable assembly at H&S Kabeltechnik

Our production PeMaC in Hungary produces customised cable assemblies with the highest precision. Through close cooperation between our teams in Austria and Hungary, we optimise internal processes to ensure an efficient and high-quality production process.

Production processes for our cable assemblies

Process Planning

In process planning, we create all the documentation required for efficient production based on customer drawings, parts lists and our own drawings. Close communication between our teams in Austria and Hungary enables us to identify potential problems at an early stage and optimise production.

During sample production, we specifically check for sources of error and also focus on possible improvements. Once completed, the samples are delivered to Austria and sent directly to the customer. Only after final approval do we start series production.

Cable cutting

With our cable cutting machines, we can cut cables precisely to our customers’ specifications. The cable is inserted, the machine cuts it according to the set parameters and, if required, insulates both ends for quick further processing or crimps the respective contacts directly onto the cable.

Every year, we process up to 10 million metres of cable with our machine pool of fully automatic, semi-automatic and various cutting machines from renowned manufacturers such as Komax. This forms the basis for high-quality cable assemblies.

Crimping

When crimping, the optimal coordination of conductor, contact and tool is crucial for standard-compliant and permanently reliable connections. Quality is ensured by measuring the pull-off force and creating micrographs in our in-house laboratory. Our equipment includes fully automatic crimping machines with tinning stations, semi-automatic crimping machines, insulation collars and crimp force monitoring, as well as fully automatic crimping machines for cables with smaller cross-sections. We process cross-sections from 0.04 mm² to 35 mm² – for maximum flexibility in all sectors such as industry, mechanical engineering and more.

Assembly

Whether push-in, screw or insulation displacement terminal technology: all options are available for the assembly of our cable assemblies. The various variants in all sizes, shapes and colours are used individually to complete your customer-specific end product.

There are no limits to your requirements, and we look forward to receiving your enquiry.

Machines

From assembled single strands to complex cable harnesses, we develop and manufacture products tailored to your individual requirements. With our state-of-the-art production facilities, our own production drawings and a team with many years of experience, we are ideally placed to meet your needs.